As would be expected, the Australian Automotive Aftermarket Association has data about the state of aftermarket manufacturing. To be sure, the sector has lost employees since the major manufacturers vacated our shores. However, the number of companies operating in the aftermarket has actually gone up, from 260 in 2015 to 300 currently. For instance, a number of engineers have left Holden, Ford and Toyota to set up engineering consultancies for product design and development.

Around 83 percent of companies in the association are either exporting or getting ready to export. The figure for companies already sending product overseas is 70 percent. The biggest markets are the US and Europe but Asia is also growing, particularly for 4WD components. Although replacement parts are part of the product mix, vehicle accessories and enhancement form the bulk of exports. Performance improvements are also part of the mix.

The association says that local aftermarket manufacturing is growing at about 10 percent per annum, which is a very respectable figure. Most of that is driven by SUVs and dual-cab utes. The latter are, of course, the prime movers for the building and associated trades. Lights, roof racks, tie-downs, toolboxes, and more are all produced in the local aftermarket manufacturing industry.

Local replacement part manufacturers also seem to be doing reasonably well because as new car sales drop, people are holding onto their vehicles for longer. This calls for replacement drive belts, air filters and other components. There are a number of smaller, niche operations manufacturing well respected performance enhancement products for the aftermarket.

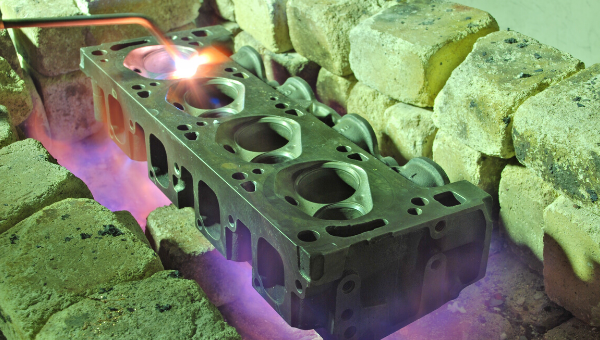

Nathan Higgins has been known for his high-performance head porting for decades, which has been the back-bone of his business. However, these days Higgins Race Heads manufactures its own range of LS, Holden and Ford heads. A new Chev head is also on the cusp of release. The business has been growing year on year for a long time. First one factoryette, then two, now three all filled with specialised multi-axis NC machines. Says Nathan, “The aftermarket scene is going off and it doesn’t show much sign of slowing down.”

Ray McDonald from McDonald Bros Racing also suggests the aftermarket is extremely healthy. He says he could stop taking orders tomorrow and still have work for the next five or six months. He suggests that the club permit scheme has helped bring cars into the market because of the reduced registration fees associated with it. People can have multiple cars on the road for the cost of just one normal registration. “They can drive their toys around and even insurance is cheaper. It’s made a huge difference,” he says.

The company sees vehicles from the 60s and 70s as its prime market. The shapes of these cars are popular (for very good reason) but of course they handle about as well as a bucket of bolts. McDonald Bros supplies bolt-in front and rear suspension and brake packages to remedy that, and they’re enormously popular. Engineered component packages that require structural modification from minor to major levels are also a mainstay of the company. Once a kit is engineered and certified, customers right around Australia have no problems with the authorities.

McDonald Bros used to work on customer cars directly but that’s changed. Over the last 10 years demand for engineered components from other workshops all over the country has grown enormously. This is a good sign because it means that classic cars are being built right around Australia. According to Ray there are far more workshops bringing classic, performance and racing cars back to life than there were 10 years ago. Over the last decade growth has been really strong and the company is investing in infrastructure for the future.

Hoppers Stoppers makes brake upgrade kits for classic cars, among other things, and demand is constant. Owner, Peter Konig, has retired from day-to-day operations and moved to Hervey Bay and says, “When I try to ring into the office I often can’t get a line because the phones are constantly busy with orders.” He continued, “It’s amazing to see what’s becoming collectible. Now, we’re even producing kits for EA to EL Falcons as well as conventional classic cars and hot rods!”

Read State of the aftermarket (Part 2). Alternatively, view full article and accompanying imagery in the February 2020 issue of Australian Automotive (page 46).